_230104102045.jpg)

_230302033137.jpg)

_230321105702.jpg)

April 18, 2024 @ 8:00 am - April 20, 2024 @ 5:00 pm

Indiana Convention Center & Lucas Oil Stadium Indianapolis, IN. Visit us at booth 5960. … Read More

April 29, 2024 @ 8:00 am - May 2, 2024 @ 5:00 pm

National Radiological Emergency Preparedness Conference will be in Dallas, TX this year. Read MoreMay 20, 2024 @ 8:00 am - May 22, 2024 @ 5:00 pm

Greater Columbus Convention Center- Columbus, OH. Come see us at Booth 933. Since the Association's founding in 1939, AIHA’s annual conference has focused on the important trends, needs, research, technologies, training, and connections that make occupational health and safety (OHS) professionals – all of whom are responsible for the safety, health, and environment of today’s workspaces – more efficient in their pursuit of protecting worker health. Read More

_240119041401.jpg)

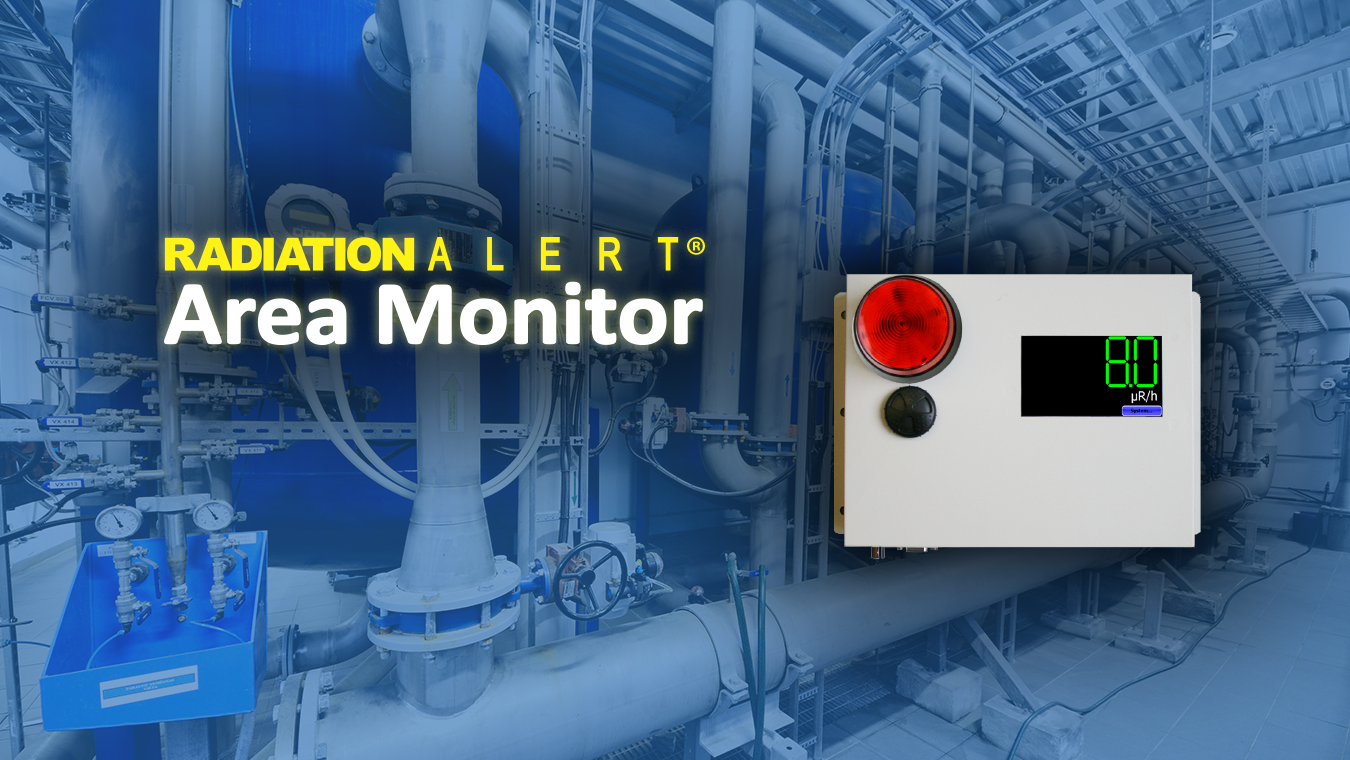

Posted on September 25, 2023

In an era where technology plays a pivotal role in safeguarding our well-being, radiation detection is critical in ensuring safety across numerous industries. For radiation detection companies like S.E. International Inc, staying ahead of the technological curve is imperative for the mission of ensuring staff, clients, and visitors of any organization dealing with radiation are kept safe and healthy. … Read More

Posted on August 23, 2023

The great English physicist Stephen Hawking once said, “Scientists have become the bearers of the torch of discovery in our quest for knowledge.” The meaning behind these inspirational words drives many scientists and researchers on a path of exploration. … Read More

Posted on July 25, 2023

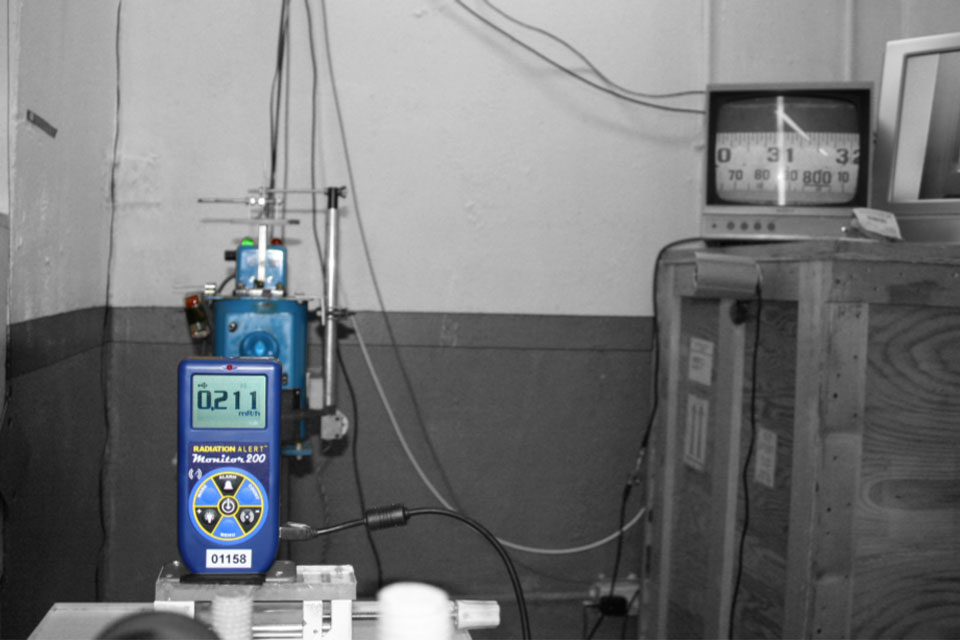

In a robust world of diverse industries where safety and precision are paramount, radiation detection equipment plays a crucial role in companies maintaining high standards. From nuclear facilities and medical centers to research labs and industrial sites, the accurate measurement of radiation levels is vital for safeguarding human health, property, and the environment. … Read MoreThank you Beth! To confirm, the source that the unit is calibrated to is Cs-127, correct? Thanks for the quick reply, this is wonderful customer service on a great product. I am really happy all around with SE and I will be sending the unit in for its annual in Q1. Happy Holidays to you all. Thank you,

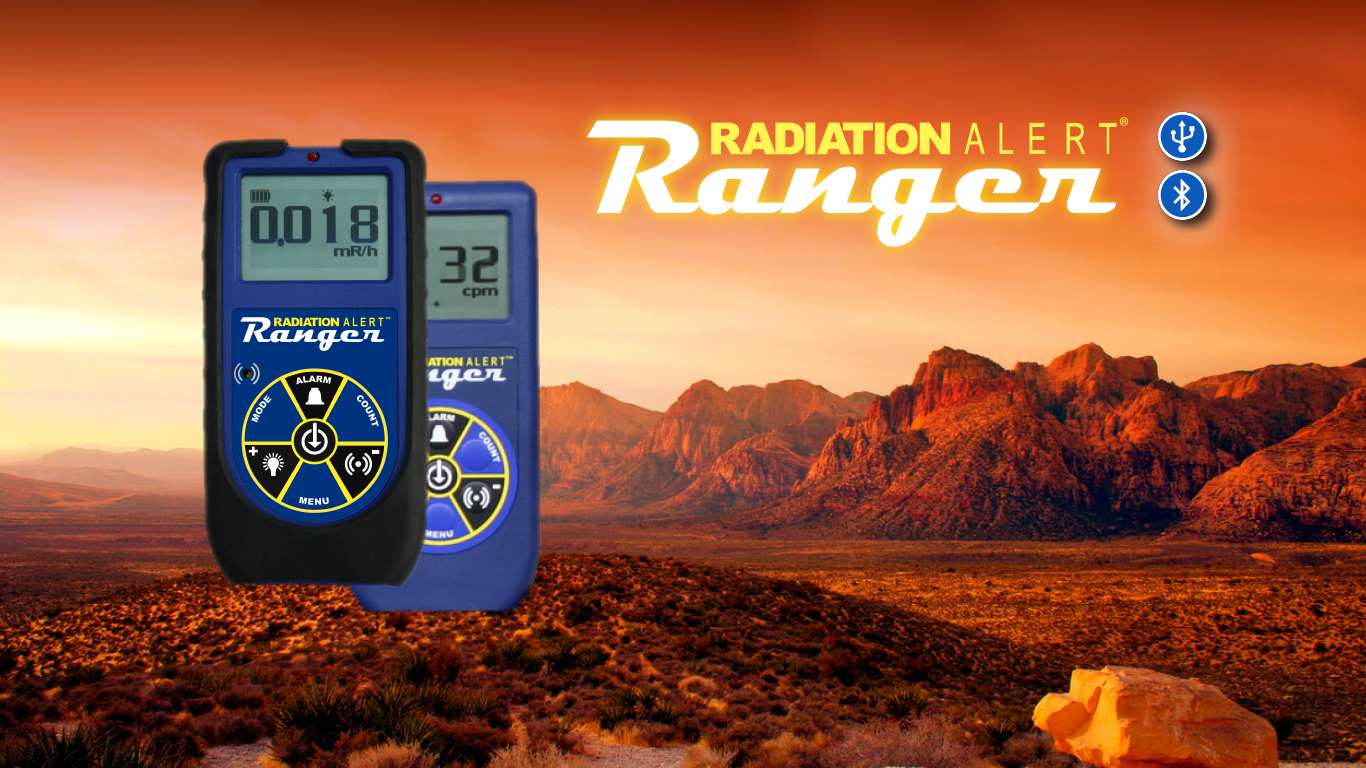

Read MoreFrom time to time, we find customers who use our products in exciting and unique ways. Meet Michael at Patriots Antiques. Michael uses the Radiation Alert Ranger® to help detect uranium in antique glassware. Here are some great things he had to say about our instruments: …

Read MoreWe recently purchased a Radiation Alert Ranger to expand our radiation safety procedures. This was a timely purchase and when a supply issue at a distributor appeared to stop us in our tracks, Beth went out of her way to help us. Without even being asked, she was able to locate another vendor with stock and put us in contact with them for the purchase. Because of her excellent customer service, we were able to continue moving forward and avoid a sizeable project delay. The Ranger itself is a great addition to…

Read More